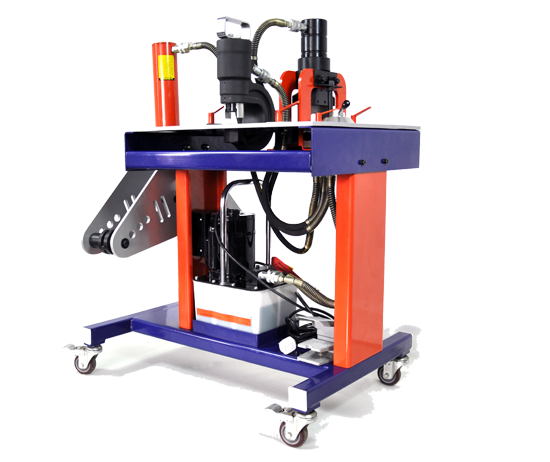

A 3-in-1 busbar machine is a unique tool that makes the work of laborers and workshop men easier. The machine bends, cuts and punches holes of bus bars which are metallic strips used to link different electrical components in a circuit. If it were not for this tool, workers would have to do the similar jobs on several equipment used at higher degree.

Busbar is made by this machine that has currently become a necessity of time, where you can produce masses for bus bars in no time. Previously, a worker had to conduct that operation manually by taking off busbars from one machine and loading it on another for bending, cutting & punching of holes. However, 3-in-1 busbar machine can fulfill all of these tasks at a single place. This simplifies the process and will save many hours for employees.