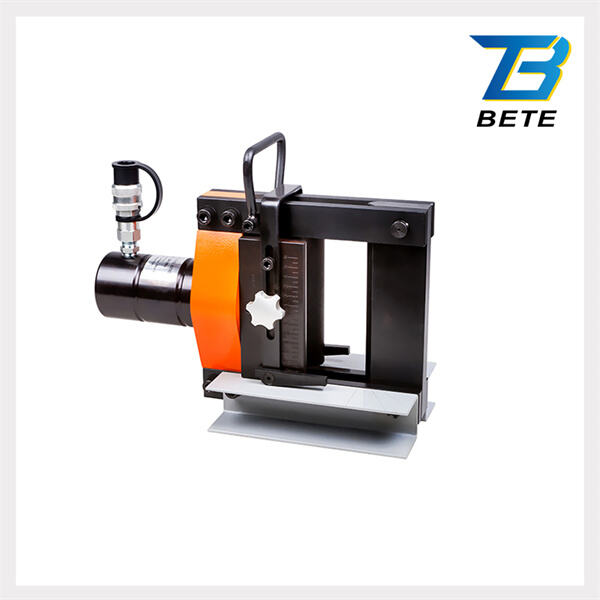

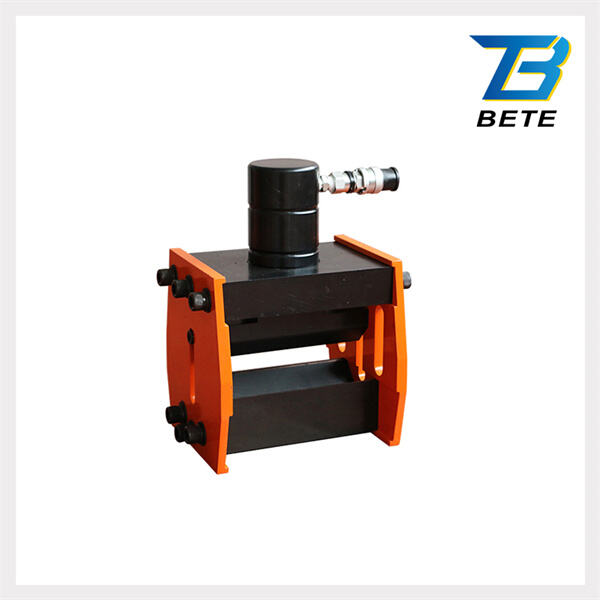

الماكينة اليدوية لثني الحافات الكهربائية المتوفرة لدينا تسمح لك بثني قضبان المعدن بسهولة... وبطريقة صحيحة أيضًا. الغرض الرئيسي من هذه الآلة الخاصة هو تسريع عمليات العمل بشكل عام؛ مما يساعدك على إنجاز الأمور بشكل أسرع. إنها خيار رائع لجميع العمال مثل اللحام، عامل الرخام أو عامل إصلاح السيارات وغيرها. نظرًا لأن الاستخدام بسيط جدًا، فلا تحتاج إلى أي خبرة تقنية أو تدريب للبدء. في الأساس، ستمكّنك من توفير الوقت والمال عن طريق القيام بالعمل بطريقة صحيحة.

يشمل هذا فوائد جهاز ثني حافات اليد الذي يسمح لك بإتمام المزيد من العمل بدلاً من إضاعة الوقت. يجعل ثني القضبان المعدنية أسرع وأكثر دقة. إذا تمكنت من ثني القضبان المعدنية بشكل أسرع وأكثر صحة، فهذا يعني ببساطة أنك ستتمكن من إنجاز مهامك بشكل أسرع وبلا تأخير. أما بالنسبة للجزء الثاني، نظرًا لأن هذه الآلة سهلة الاستخدام، فلا داعي للقلق بشأن الحاجة إلى أي موهبة خاصة أو تدريب لاستخدامها. إنها سهلة ويمكنك البدء في استخدامها في أي وقت للحصول على النتائج التي تريدها! إنها ضرورية للغاية لزيادة الإنتاجية حيث يمكنها مساعدتك على القيام بالمزيد في وقت أقل. وهذا يمكن أن يؤدي مرة أخرى إلى تحقيق الأرباح - وكذلك المساهمة في شخصيتنا العاملة بجد.