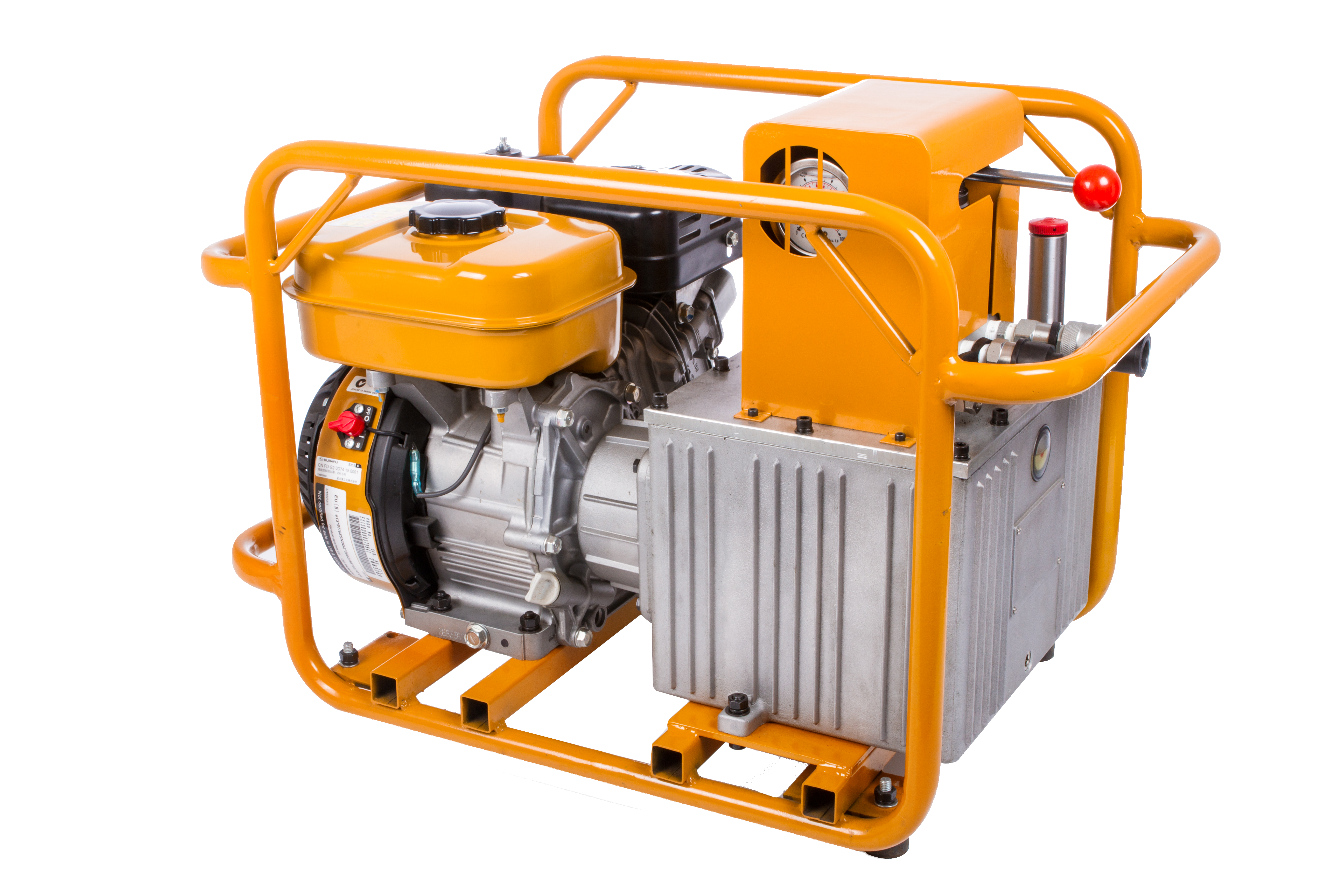

هل سبق لك أن تساءلت كيف يقوم الميكانيكيون بشد البراغي لمachinery العملاقة؟ يمكن أن يكون ذلك تحديًا كبيرًا! يتم استخدام المفتاح الهيدروليكي لهذه المهمة، مما يجعل العمل أسهل. أحد الطرق هو باستخدام مفتاح هيدروليكي، مما يجعل شد وتفكيك البراغي أكثر سهولة. يعمل عن طريق استخدام قوة النظام الهيدروليكي (على سبيل المثال، السوائل التي تحتوي على الزيت). هذه القوة تبسط العمل على الآلات الكبيرة والبناء.

يُعثر عليهم بشكل متكرر في البيئات الصناعية، مثل المصانع والمواقع الإضافية للشركات لأن هذه المفاتيح الهيدروليكية تم تصميمها بالفعل ل为抓 الأبراج والمكسرات. إنها مثالية للأجهزة الكبيرة والمعدات الثقيلة. الدقة هي على الأرجح أفضل فائدة للمفاتيح الهيدروليكية. بمعنى آخر، تضمن لك أنك تقوم بشد البراغي بشكل صحيح. إذا قمت بذلك في حالة كونها فضفاضة جدًا، فإن الجزء سيتفتت عندما يتم ضغطها معًا. قد يكون الأمر مختلفًا - ربما كان يجب إخراج البرغي، ولكن إذا كان الأمر كذلك، افعل ذلك الآن قبل أن تلمس الأشياء بقوة كافية وتسبب لهم التفكك. المشكلة الحالية هي ما إذا كان هذا أو ذاك البرغي سيصبح مشدودًا جدًا بحيث لا أستطيع إزالته لاحقًا دون كسره وتدميره. لذلك من الأهمية بمكان تحقيق شد مناسب وسليم. واحدة من أكبر الفوائد للمفاتيح الهيدروليكية هي أنها خيار أكثر أمانًا مقارنة بأنواع أخرى من المفاتيح. كما أنها تسمح للإنسان بعدم سحب القوة القصوى على أي كابل طويل (سحب)، مما يقلل من خطر الإصابة.