Hydraulic wrenches are brute-force devices that screw or unscrew bolts at closer tolerance than workers can. How well can they give you just the right amount of torque is something to consider with these wrenches. Torque is the force that assists in turning or twisting something, such a bolt. The consequences of an incorrect torque can be problems similar to a bolt that is too tight or too loose. This in turn may result in a safety problem or failure of equipment. At Bete, we also realize that knowing what influences accuracy in torque output of hydraulic wrench systems can aid in making informed decisions when using these same tools.

Which Factors Affect the Accuracy of Torque Measurement for Hydraulic Wrench Systems?

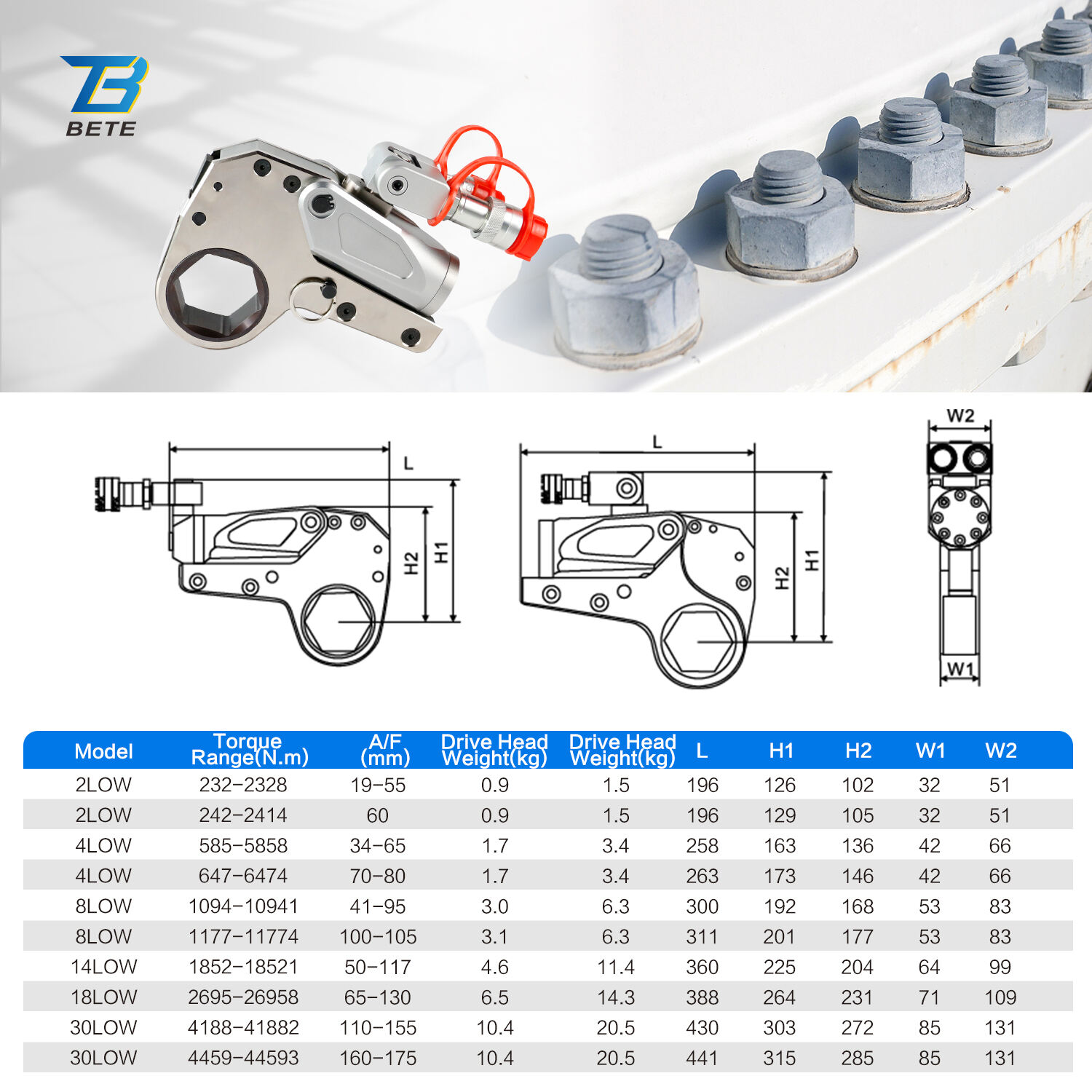

A variety of factors can influence the degree of a hydraulic wrench’s torque readings. First, hydraulic pressure is everything. Too little pressure and the wrench won’t do as much work as it should, so the torque will be off. Should you apply too much pressure, the wrench could snap or the bolts be over-tightened. Other consideration is the workmanship of hydraulic wrench. Wrench accuracy is considerably positively affected by the quality of the wrench itself as well as the design of the wrench, which is the second most important factor. Certain wrenches with a compact design can fit inside tight spaces for use, while other wrenches are designed for larger jobs. The added leverage of the wrench length can also be the reason for the higher torque measure. Torque is related to force, so a longer wrench can generate more force. The condition of the bolt/nut being tightened is also a factor that affects the accuracy of torque. Rusty or defective screws can create a barrier to the torque desired.

Which Hydraulic Wrench to Select Regarding Greatest Torque Accuracy?

If you’re going to choose a hydraulic wrench, the last thing you want is something that won’t provide you with necessary torque. The manufacturer’s specifications, such as the maximum pressure it can handle, are a good place to start. Use the wrench that best fit according to the job at hand. See if it includes things like an adjustable pressure setting, which can adjust the torque output for more precision. Also, consider the size and weight of the wrench. A lighter-weight wrench may feel easier to handle, but it also must be strong enough for hard work. Reviews from other users will help here, too. Their experiences can offer you insight in so far as to how dependable and accurate the wrench is. Finally, think about taking a training class on how to use the wrench. The best tools can have flawed outcomes if not used properly. At Bete we want to give you the tools and knowledge, so that you succeed in your applications.

What Challenges Influence Hydraulic Wrench Torque Output Accuracy?

Hydraulic wrenches are strong yet effective tools used to tighten or loosen various types of bolts and nuts. Yet sometimes they don’t do as much good as they should, and this impacts their ability to accurately apply torque. There are a number of basic problems which can cause the torque produced to not be accurate. One big problem is leaks. If there is a hydraulic leak, it can allow the wrench to lose pressure. That means it will not be able to tighten bolts as much as is necessary. A second problem is trying to tighten screws with the wrong size of wrench. If the wrench is too large or too small, it could deliver an incorrect amount of torque. The state of the tool makes a difference, too. If it's old or broken down, a hydraulic wrench might not function appropriately. Occasionally, grime and dirt may accumulate inside the wrench also and this can cause it to be incorrect. Keeping it clean and in good repair is key. The type of oil for the hydraulic system is also very important. If the oil is dirty or low, that can cause the wrench to not work properly. And, finally, there is the operator. This is due to error when the person turning the wrench doesn’t know how to use it properly. For instance, lack of keeping the tool still or incorrect settings leads to misguided indicates of torque. At Bete, we are aware of these problems and try to offer excellent tools in order to avoid running into any of these issues.

How Can I Ensure that a Hydraulic Wrench Will Keep Torque Accurate?

Some of the most common mistakes and bad practices that get in the way of hydraulic tightening are Avoid these to keep your hydraulic wrenches working accurately. First, regular maintenance is key. How a car has to undergo oil transitions is how hydraulic wrenches have to be checked on regular basis. Operators should check for wear and abuse on the wrench. This involves inspecting for leaks and examining the hoses for cracks. Should any issues be discovered, they will need to be taken care of right away in order to avoid further damage. One more great method to keep your hydraulic tools functioning for a longer period is by utilizing the right hydraulic fluid. The fluid has to be colorless and must be the right fluid for the tool you are using. Using dirty or wrong fluid will reduce its performance. Besides, I would also suggest that you clean the wrench perfectly. After utilizing the tool, you should wipe it clean. This way, you can stop the accumulation that can cause the scale to be erratic. When not in use, store the wrench in a dry location and avoid exposure to moisture and extremes of temperature. By helping this, it will be more resistant to any injury. In addition, training is highly important. The operators should be aware of the way the wrench should be used correctly. They also need to know the appropriate torque for different jobs. We at Bete have training material and support for you regarding the best practice of working with hydraulic wrenches. Lockers will have peace of mind when assurance is given that the hydraulic wrenches will always have the accurate torque output while using these steps.

What Causes Hydraulic Wrench System Torque Output Failure And How To Solve Them?

Identifying and rectifying the error is the only alternative when a hydraulic wrench fails to deliver the expected torque output. Discovering a flaw is the focal starting point. The first thing to do is to scan the hydraulic system for possible leakages. If you discover any oil on the pavement or around the wrench, it could possibly indicate a leak. The issue might generally be easily tackled by patching the leak. Additionally, you will want to check the level of hydraulic fluid to make sure it's at the right one. If it's below the right level, then add the Ingestible hydraulic fluid of the right type. Furthermore, you should definitely check and ensure the fluid is clean before you go ahead. A wrench might not be operational due to dirty fluid. After the fluid is tested, the hoses and connections must be checked. Look for signs of damage. Damaged or loose hoses may need exchanging. Besides, the setting on the wrench should also be checked. Ensure that the torque setting is right for the task. Nevertheless, some operatives will set the torque incorrectly resulting in a bad output. In case the tool appears to be in good condition and it's still not functioning properly, some calibration might be needed. Calibration is the process that makes the tool sure that it is reading the correct torque. In the end, if you fail to locate the fault, consult the reference or get in touch with Bete for advice. The professionals at our company could assist you in finding the problem and in providing various solutions. That will give you the opportunity to handle problems that often arise in handling torque output in hydraulic wrench systems easily and be sure that the hydraulic wrench will work as you required it to, exactly, at given times.

Table of Contents

- Which Factors Affect the Accuracy of Torque Measurement for Hydraulic Wrench Systems?

- Which Hydraulic Wrench to Select Regarding Greatest Torque Accuracy?

- What Challenges Influence Hydraulic Wrench Torque Output Accuracy?

- How Can I Ensure that a Hydraulic Wrench Will Keep Torque Accurate?

- What Causes Hydraulic Wrench System Torque Output Failure And How To Solve Them?