A Step-by-Step Guide

Step 1: Measure the Cable You Want to Clamp. This is crucial as the correct sized grip plays a very important role. If your choice of the grip is too small, it may not be able to keep hold on the cable tight enough and this could trigger some issues. If it is too large, the grip may not hold the cord or even damage, the cable will come off.

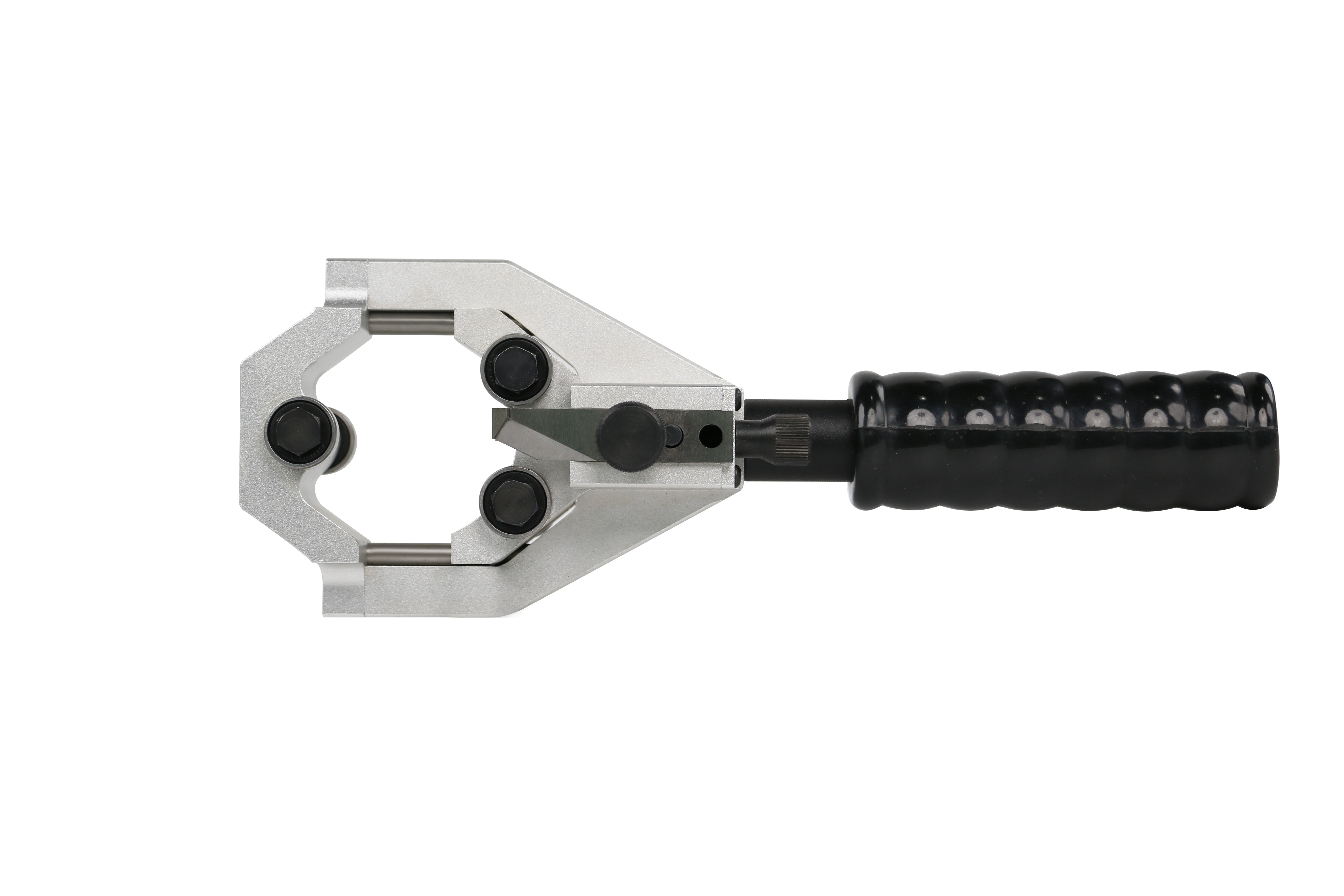

After you choose the right grip for your needs, it has to be opened margin. Mortgage on moral hazard nearly all cable cord grips have a screw or clamp that you can loosen to make them unfold. Following this, insert the cord in the grip and afterwards secure it by tightening up off again enjoying or clamp. Ensure that the grip is tight enough so as to prevent slipping, but also not too tight such that it will hurt or compress/cause damage to whatever cord is going through.