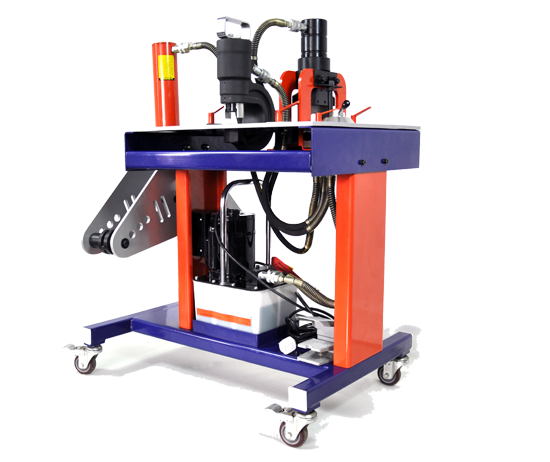

Did you ever think, Metal parts get cut into correct shape how? It might sound complicated, but the solution is actually hydraulic angle cutting machines! These are machines that have been created to make cutting metal simple, and they were designed also with accuracy in mind. These are tools that assist employees in making metal pieces to the exact same fit as their respective project.

This hydraulic angle cutting machines is equipped with sharp blades for metal to be easily cut. Commonly, these blades are used for extremely hard materials as cutting through them does not take much effort and they work like a knife on the butter. Machines also have a robust foundation where metal is kept fixed while cutting down into different pieces. Clean and efficient cuts: This is the biggest advantage of this machine, as it provides stability so that all your laser cutting jobs will come out with precise edges in metal sheets duly cut according to an accurate measurement.