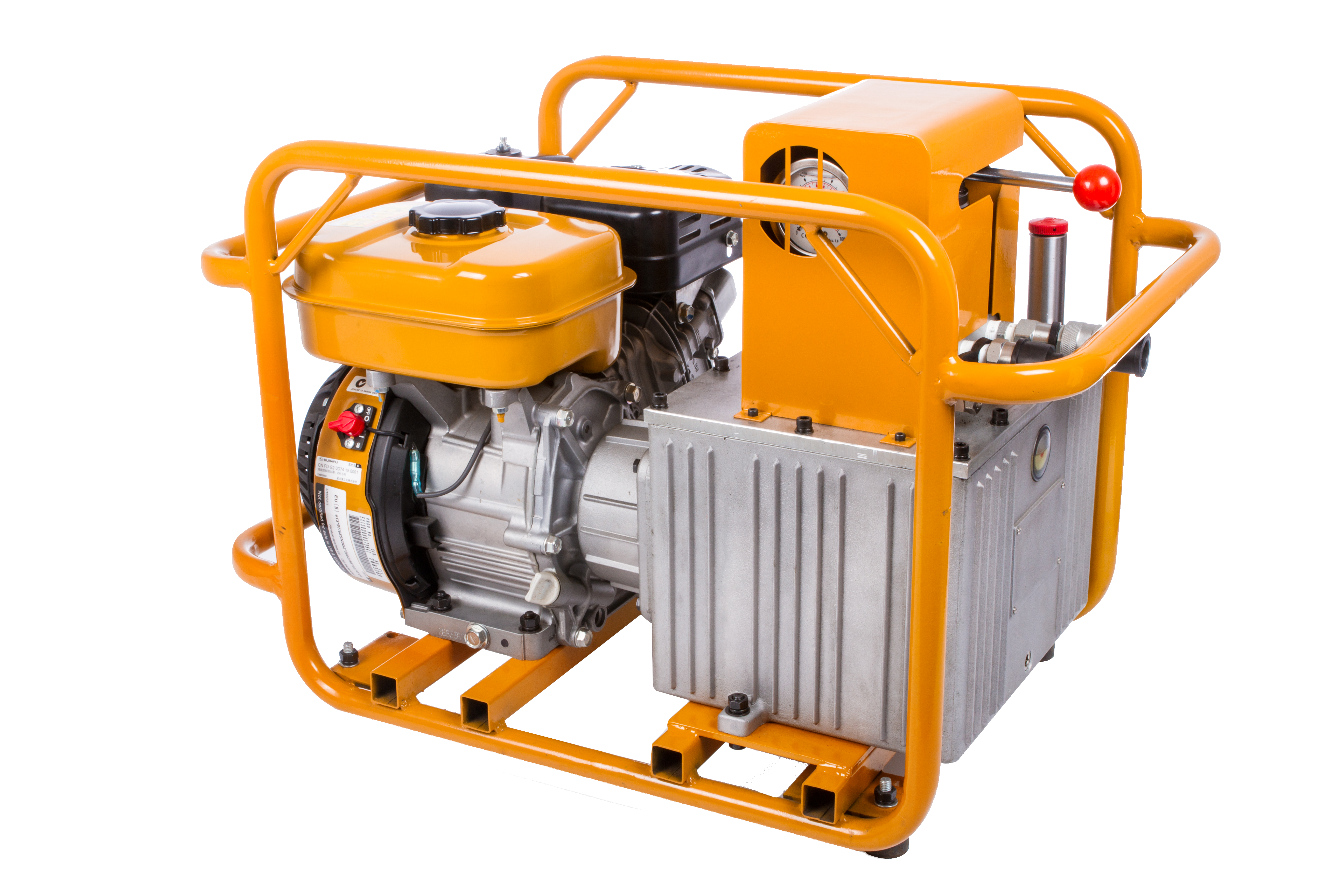

The hydraulic compression tool Hydraulic Press Machines help the workers to work in more effective way and quicker manner. It is often used in bonding variety of materials together which is helpful for many applications. This is especially common among workers in different fields such as repairing tools, like welding and plumbing and fixing cars because it helps them to make their work much easier.

Hand hydraulic crimping tools allow workers to do work a lot more faster than in comparison of getting everything done manually. Fluid power is the compressive force on which press runs and thereby helps workers to get rid of such big muscles requiring high energy. They are designed to operate quickly and efficiently for employees, so they can work on projects while saving a lot of time. This is very helpful in doing things like quick operation such emergency or just getting any job done as soon it could be. This way, workers can work more effectively and will not have to fear the consequences of missing important information